Hongchang Pump offers a complete range of slurry pumps for medium and heavy duty slurry applications, including cyclone feed, spirals feed, mill discharge, tailings disposal, filter feed, effluent discharge.

Hongchang Pump manufactures a large number of high-quality slurry pumps and pump parts for various industries and applications. Slurry pumps come in different types, sizes, speeds, metals, and solid handling capabilities. Our slurry pumps are designed to transport liquids containing suspended solids and non-suspended solids. We provide high-quality industrial slurry pumps for mining, coal preparation plant, power plant, building, waste management, and many other industries.

Hongchang Pump produces high-quality metal and rubber replacement parts that are fully compatible with Australia famous brand pumps, providing value to customers through fair pricing and delivery times that are the most reasonable in the market. We have a large inventory of slurry pump parts, all of which can be interchanged with Australia famous brand slurry pump parts.

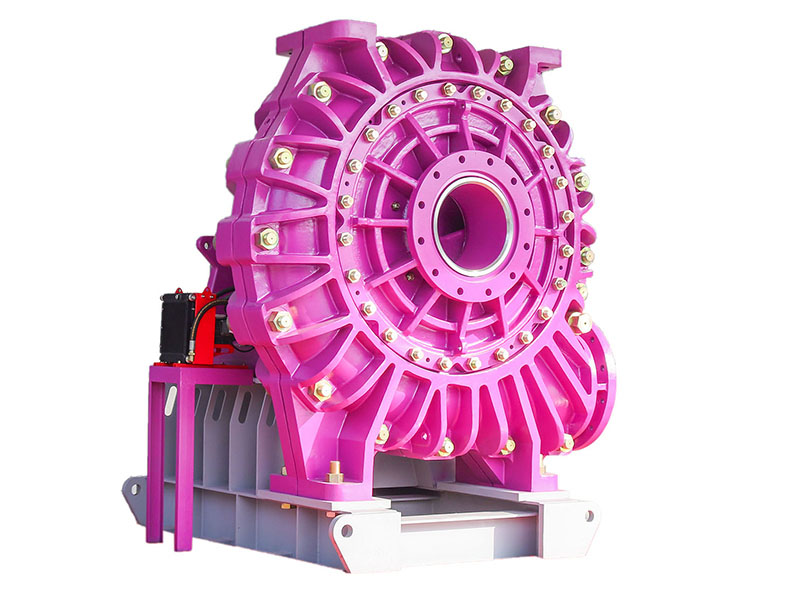

The industrial pumps for slurry solids pumping.

Slurry pumps can handle some of the most demanding pumping applications, with each pump having the features you need: portable, powerful, compact, versatile and easy to maintain.

Our slurry pumps have a robust structure and safer protection measures, and can be used for stable conveying of abrasive materials, minerals, and corrosive materials.

Our pumps are known for their quick delivery time and efficient conveyance of abrasive and corrosive slurries in a wide range of industries, including mining, mineral processing, pulp and paper, and wastewater treatment.

Our durable slurry pump design employs specialized casing and wear-resistant lining technology to maximize normal operating time.

Hongchang Pump provides many series of slurry pumps with interchangeable rubber lining and hard alloy lining.

Rubber-lined slurry pumps have longer wear life in applications with fine particles, where the average solid particle size is less than 250 microns and the maximum particle size is 10 millimeters. Metal-lined pumps are typically recommended for handling slurries containing larger particle sizes.

Slurry pumps are available in various types, including centrifugal pumps, positive displacement pumps, and vortex pumps. Centrifugal slurry pumps can feature shafts supported between bearings with split casing or rubber- or metal-lined casing. They can be configured as horizontal, vertical suspended, or submersible pumps.

Several factors influence the lifespan of pump equipment. Selecting a suitable pump for the specific application, operating it correctly, and ensuring proper maintenance can help extend its lifespan. Factors such as speed, material selection, and design often have significant effects on the equipment's durability.

Industrial pump systems can experience failures due to various reasons. These may include incorrect installation, improper sizing of motors, insufficient maintenance, lubrication errors, or speed-related issues. Failures can also occur if the pump fails to start, experiences power disruptions, encounters impeller blockages or wear, has improperly installed suction pipes, or suffers from damaged or worn seals and gaskets.

Industrial pump systems should be regularly inspected and maintained. This involves checking for any leaks or blockages, inspecting the motor and bearings, changing the oil, and testing for proper flow and pressure. Moreover, it is necessary to clean the system periodically, replace worn-out components, and perform preventive maintenance as required.

Our friendly team at Hongchang Pump would be more than happy to assist you further with any pump solutions, delivery information or questions you have.